First step in batch production

As you may know, factory batch production is a difficult challenge with a very high cost of errors. To avoid mistakes, we will take some preliminary steps to be sure everything will go well. A few days ago we took these first steps, while still preparing all other crowdfunding things like videos, campaign copy, and use cases.

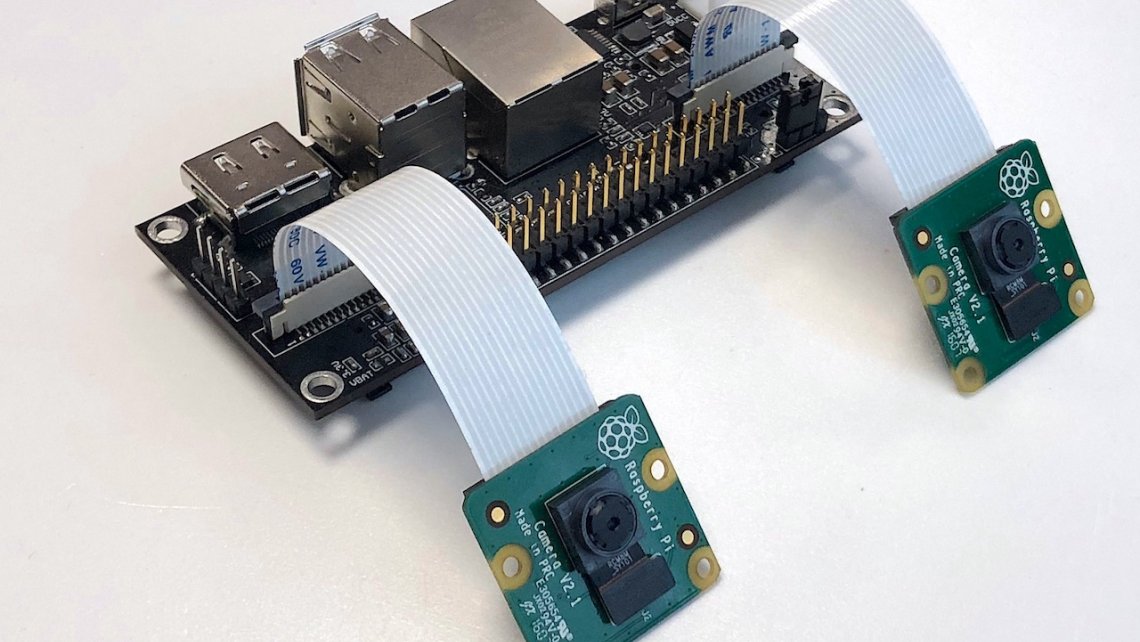

We already have working prototypes created by our local manufacturer for testing purposes. But for the main batch we chose a big partner in another country. In our case, batch production includes three steps:

1. Making prototypes (20 pieces)

At this step we and the manufacturer check that everything is okay with our schematics, PCB, and components. For example, we found that we need to change the MicroSD connector because our original part is EOL and there is a market shortage.

2. Pilot run (several hundreds pieces)

This step comes right before all batch manufacturing and is intended to find hidden bugs and possible PCB or component problems. In the worst case, we would have to make all the PCBs over again with fixes, or have to buy alternative components if we encounter quality issues. In best case scenario, the manufacturing is successful and we go to the next step.

3. Main batch production

This is the final step when all devices are fully assembled.

So we are glad to inform you that on the 13th of November our manufacturing partner received our payment and started on the first step. Estimated production time is three weeks (including BOM buying, PCB production, and assembly).